Technical Specifications

For Fully-Automatic Double-Deck & Double-Chamber Laminator

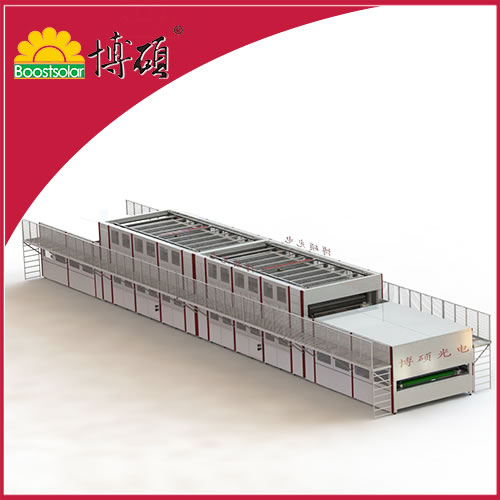

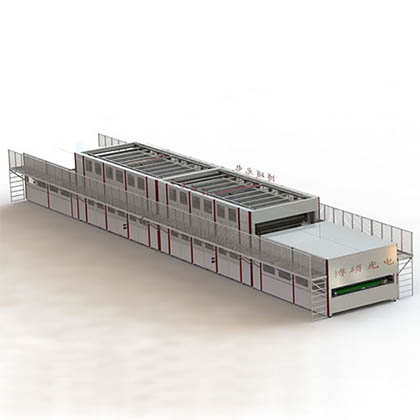

| Name | Fully-Automatic Double-Deck & Double-Chamber Laminator | |||

| Model | BSL2456OAC-DD | |||

| Equipment Parameters | Power Supply (can be customized) | AC380V 3phase 5 line | Control Board | Touch Screen |

| Total Power | 330KW | Normal Working Power | ≈130KW | |

| Effective Laminating Area | 2400*5600 | Chamber Layout | Double-deck Double-chamber | |

| Compressed Air flow | ≥400L/min(each chamber) | Unit Weight | ≈68T | |

Structure Specification

Total four laminating chambers, vertically laid out in upper & lower two decks. Each laminating chamber is independent and can work independently; the four laminating chambers use the same loading and unloading units. The loading unit adopts synchronous belt conveyor, the unloading unit adopts roller conveyor which is equipped with a chiller to cool down the finished panels.

Heat oil heating type, with 2 sets of 81KW heating station and an independent external electric control cabinet.

The front and rear parts of the main machine are covered with shield plates as the protection structure which is convenient to be quickly opened for maintenance and replacement of the vulnerable parts and consumable supplies.

The roller brush device is installed in both upper and lower chambers to clean the surface residue on the transmission Teflon sheet.

Drawing: Outside drawing

Main Technique Parameter

Effective Laminating Area: 2400 mm × 5600mm (can be customized)

Overall Dimension: 25370mm×3360mm×2900mm (only laminator exclude auxiliary tools such as vacuum pump and heating station)

Heating Type: Heating conductive oil

Compressed Air Pressure: 0.6~0.8MPa

Working Vacuum Degree: 100~40Pa

Evacuation Speed: First chamber: ≥600L/s, second chamber: ≥70L/S

Precision of Temperature Control: ±1.5℃

Temperature Control Range: Room Temperature–170℃

Temperature Uniformity: Laminating area≤±2℃

Height of Laminating Chamber: 30mm

Evacuation Time: Depending on the process, suggesting: 5~8min

Upper Cover Moving Range: 200mm

Equipment Characteristics

– High Capacity

Compared with normal double-chamber laminator, this type of laminator is 3.6 times capacity than the normal laminator.

– Less floor space

Under the condition of same capacity, and comparing with the normal double-chamber laminator, this type of laminator only requires 1/2 floor area than the normal one; therefore, it decreases production cost by saving workshop space. With the same capacity, equipments of this type are more concentrated installed so as to save labor cost by reducing manpower operators.

– Automation

Four chambers, with upper and lower two-deck design, automatic loading and unloading, intelligent control, can be linked to run with the automatic production line.

– Convenient maintenance

Inner structure is designed to be convenient for maintenance and checking running status for the operator, as well as convenient to replace the vulnerable and consumable parts. With the simple frame structure, it enables the maintenance personnel to be closer to any spare parts for easier maintenance.

– Low power consumption

Upper and lower chambers adopt two heating stations to decrease energy consumption so as to save user’s output cost.

– Strong adaptation

It fits to the laminating and encapsulation for different solar modules of mono and poly silicon cells, thin film and double-glass modules; and can also meet the operating requirements of normal industry environment and laboratory environment.

– High flexibility

Chambers of each deck are independently designed which have their own independent vacuum and pressure system. The two-deck chambers can coordinate working with the help of lifting conveyor; however, a single chamber can be independently operated. When one of the chambers or chambers at one floor gets out of order; it will not affect the chamber operation on the other floor.

– Module lift-pin system can be provided according to requirements.