Depict

1. Cell specification: 156-166 mm, Half cell,3, 4, 5 bus bar and MBB.

2. Cell thickness: 160–250μm

3. Allowable warpage: ±2mm

4. Type of materials: Mono/poly crystalline silicon

5. Transmission height: 950±20mm

6. Repeat positioning deviation of panels on the transmission unit: ±5mm

7. Transmission speed: Speed before lamination is within17m/min adjustable; the speed after lamination is within 22m/min adjustable.

8. Uptime≥95%, Except maintenance, calculated by continuous work for one year.

9. Life Time ≥10 years, Equipped with manual/automatic switching function.

10. Human-machine interface system, multi-user classified login, convenient for the sort management of process parameters and basic operation, avoid parameters being faulty modified by others.

11. Material level sensor works reliable, highly system interlocking and fault toleration, transmission control with conditional detection, in addition to the manual control to avoid error operation.

12. The lay-up unit ahead of the lamination has reserved docking signals to the automatic stringer and laying machine.

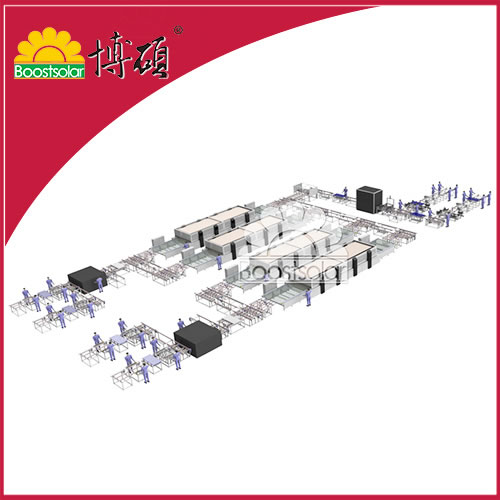

1. Characteristics Overview of the Boostsolar Production Line

1.1 This production line is designed based on customer`s request and custom-made for the customer. The line arrangement are considered as the most economical and practical, and it can realize the maximum capacity of the equipment. This line is suitable for different kind of module production with wide applicability and high mechanization degree.

1.2 Conveying units adopts PU synchronize belt to transport, with the characteristics of

smooth transmission, low noise, long using life and etc. So it can prevent the displacement of module during the transmission, and no damage to the glass and coatings, so that it can ensure the safety of transmission.

1.3 According to module size, it can laminate 3 or 4 pieces of different specification modules at one time in effective laminating size. Customer can choose the loading type(type of 3 in one row or type of 2 in each two row ), the loading is controlled by the program.

There is device in the front/back end of laminating transmission unit to prevent the module accidentally fall down, it will avoid the loss which is caused by the sensor malfunction.

1.4 The logistics channels and maintenance channels are taken into consideration when designing the production line. Adopts automatic folding channel in some parts of conveyor units to make the operator or materials in-out smoothly. It will also not influence the product pass smoothly(This structure has been obtained the national patent).

1.5 Designed as No Scratching and No Subfissure, the part which is contacted with the module is adopt to the soft material .Reasonable placement of transmission distance and working surface ,to make the bending deflection of glass reduced to minimum.

1.6 Electric circuit of each transport unit adopts distributed type, which convenient for

installation and maintenance.

Control system of conveying line adopts touch screen and PLC control, with Intelligent detection system and automatic fault alarm systems, which ensure high operational reliability of the production line.

1.7 Reasonable software is edited to ensure modules being conveyed in the best route, avoid the cycle time waste and save energy.

1.8 Recipe editing and selecting function can store product types and operation method frequently-used, which make product change faster.

1.9 Accessories are supplied by international and domestic well known brand, which can well ensure the high quality of the whole line.

1.10 The main functional units adopt steel structure, the exterior pensu processing, solid, durable, good stability, increases the service life of equipment, assembly line transmission unit adopts industrial aluminum structure.

1.11 Pictures of equipment drawing attached only for reference.

2.2 Mechanical Characteristic

2.2.1 Transmission parts of conveyor line after lamination adopts heating-resisting material, to ensure the normal running of equipment.

2.2.2 According to production requirements, equipped with PLC and touch screen to display the unit work status, avoid the whole line stop when some unit adjusts.

2.2.3 Pump, motor and other mechanical devices have good performance and service life, moisture proof and anticorrosive equipment and some antirust metal parts make equipment maintenance quick and convenient.

2.2.4 Equipment quality conform to ISO9000 standard.The equipment appearance is pretty and beautiful, oil paint color is teeth white knit , meet the requirements of customers

3.3 Safety System

3.3.1 Part of equipment has air source, vacuum and other test function, if air source and sucker vacuum don’t meet the running conditions, there will be an alarm and all related running action will be stop

3.3.2 After emergency power off, do not make the module break uttermost. Set the necessary protection procedures (Except human factor influence)

3.3.3 There are well-equipped safety protection device. Stick the warning label,alarm and audible and visual indication of malfunction according to the international standard.

3.3.4 Comply with the standards and the relevant provisions of the nation,cable goes through trunking, air pipe outside has protection, service port and service door designs suitable, internal neatly. Electrical components layout is tidy and standard, each transmission line and pneumatic element concentrated in the cabinet, each part has clear comment, line number, pipe has clear mark and one to one correspondence with drawing.